The biggest advantage of using cold forming is that the products tend to have a tight tolerance and tight section properties as well. In turn, this permits for less machining the Cold Drawn Welded Tube with an improved straightness. Hence, the product has a better formability. Meta Engitech’s tubes are widely used in automobile industry and also for manufacturing material handling equipment, special purpose machines, hydraulic equipment, textile machinery, etc. Just like Seamless Precision Tubes, they too have low carbon content, are highly malleable, suitable for bending.

These tubes are used for various applications like :

- Automoblies & Mechanical

- Propeller Shaft

- Shock Absorber Tubes (SSID)

- Bobbin Tubes for textile industry

- Telescopic Front Fork Tubes

- Hydraulic Tubes

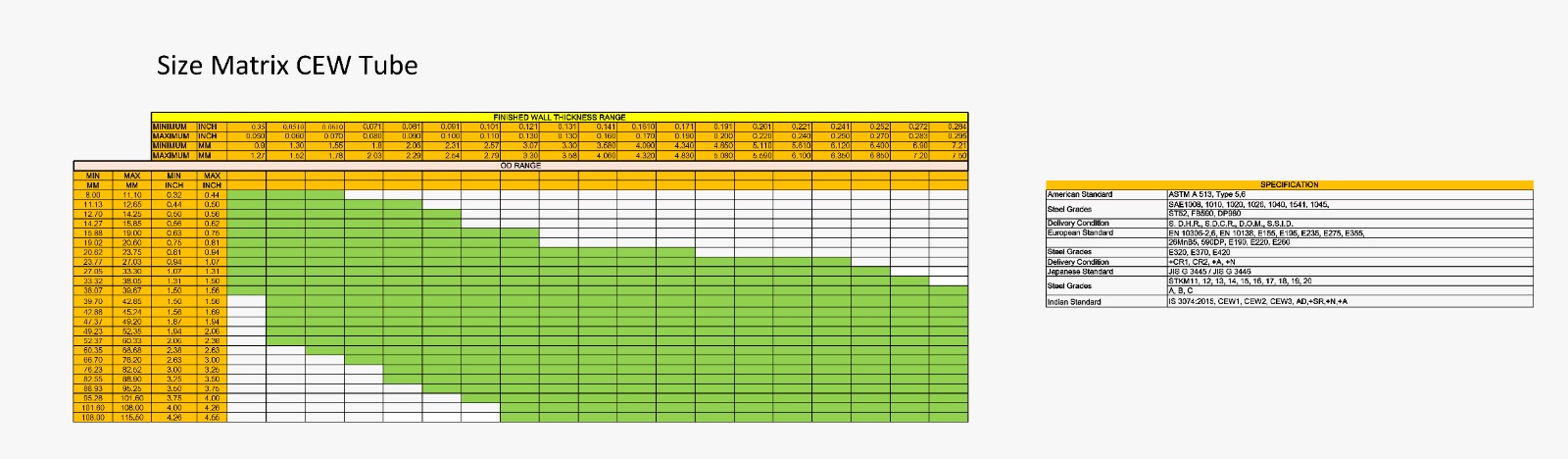

Size Range

CEW (Cold Drawn Electric Welded) or DOM (Drawn over Mandrel)Tubes from 6mm OD 8mm to 112mm OD with thickness from 1mm to 7.5mm

DOM Tubes

CEW Tubes